skid steer differential A British agricultural company, Hornsby in Grantham, developed a continuous track, which was patented in 1905. The Hornsby tractors featured a track-steer clutch arrangement. See more Compact Track Loaders. TL65RS8,575 lbs • 67 hp. TL75VS9,205 lbs • 74 hp. .

0 · skid steer wheel design

1 · skid steer vs mecanum wheel

2 · differential steering wheel

3 · differential steering vehicles

4 · differential steering definition

5 · differential steering clutch brake

6 · controlled differential steering

The Harford Quick Couplers fit any excavator from 1650 to 30,800 lbs. They are made to the highest build quality, easy to install and simple to operate. Which quick coupler do I need? Quick couplers and pin grabbers designed to meet your specific needs. Tool Free Coupler – Ideal for mixed fleet rentals – dedicated system. Safelock.

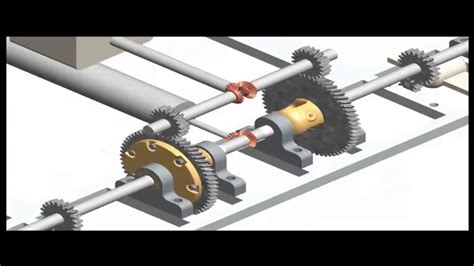

Differential steering is the means of steering a land vehicle by applying more drive torque to one side of the vehicle than the other. Differential steering is the primary means of steering tracked vehicles, such as tanks and bulldozers, is also used in certain wheeled vehicles commonly known as skid-steer, and . See moreA British agricultural company, Hornsby in Grantham, developed a continuous track, which was patented in 1905. The Hornsby tractors featured a track-steer clutch arrangement. See moreThere are several mechanisms that have been developed to vary the torque applied to different sides of a vehicle. These include clutch-brake steering, braked-differential steering, . See more• Tanks, armored personnel carriers, armoured vehicle-launched bridge, self-propelled anti-aircraft weapon, and similar military vehicles• Bulldozers, excavators, tractors, snowcats, trenchers, and other heavy equipment See more

Depending on implementation, friction between drive mechanism and ground, and available power, a vehicle with differential steering may have a zero turning radius or a curb-to-curb turning circle equal to the length of the vehicle by driving each side at . See more• Tank steering systems See moreSkid steering uses two parallel rows of two or more wheels (or tracks) and therefore wheel . Learn about the advantages and disadvantages of various types of mobility for .

Skid steering is accomplished by creating a differential velocity between the inner and outer .Differential Drive Robots. These drive bases typically have two or more in-line traction or omni .Learn about different wheel arrangements and control mechanisms for robots, such as .

Differential steering is the primary means of steering tracked vehicles, such as tanks and bulldozers, is also used in certain wheeled vehicles commonly known as skid-steer, and even implemented in some automobiles, where it is called torque vectoring, to augment steering by Skid steering uses two parallel rows of two or more wheels (or tracks) and therefore wheel sideslip must occur everywhere except for a single point on each side. This point moves around depending on contact force and friction between wheels and grounds. Learn about the advantages and disadvantages of various types of mobility for robots and rovers, such as tracks, skid steer, differential drive, and more. Compare the mechanical complexity, weight capacity, power usage, and maneuverability of each drive option.

Skid steering is accomplished by creating a differential velocity between the inner and outer wheels. Explicit steering is accomplished by changing the heading of the wheels to cause a change in heading of the vehicle. Experimental results are gathered to provide information regarding power draw, individual wheel torque, and position information.Differential Drive Robots. These drive bases typically have two or more in-line traction or omni wheels per side (e.g., 6WD or 8WD) and may also be known as “skid-steer”, “tank drive”, or “West Coast Drive”. The Kit of Parts drivetrain is an example of a differential drive.Learn about different wheel arrangements and control mechanisms for robots, such as differential drive, skid steering, tricycle drive and Ackermann steering. Differential drive is the most common and simple method to drive and steer a robot using two independently driven wheels. Skid steering has advantages for military armoured vehicles because it gives greater internal hull volume and improved manoeuvrability. The steering performance of an 18t 6×6 skid-steered.

skid steer wheel design

capable of slip prediction for skid-steer wheeled mobile robots (SSWMRs). The proposed model outperforms the state-of-the-art in terms of both translational and rotational prediction error on a dataset composed of more than 6km worth of trajectories traversed by a skid-steer robot. We also publicly release ourLearn about the history, operation and use of skid-steer loaders, compact heavy equipment with lift arms and zero-radius turning capability. Find out how they differ from conventional front loaders and what safety precautions are needed. Skid Steer / Differential Drive. Here is some math for 2 and 4 wheel differential drive vehicles, 2 wheels and a castor, or skid steer tracked vehicles. Arc based commands. The basic skid steer equations are: velocity_right = w (RADIUS_OF_ARC_TO_DRIVE + WHEEL_BASE/2) velocity_left = w(RADIUS_OF_ARC_TO_DRIVE – WHEEL_BASE/2)Differential steering is the primary means of steering tracked vehicles, such as tanks and bulldozers, is also used in certain wheeled vehicles commonly known as skid-steer, and even implemented in some automobiles, where it is called torque vectoring, to augment steering by

Skid steering uses two parallel rows of two or more wheels (or tracks) and therefore wheel sideslip must occur everywhere except for a single point on each side. This point moves around depending on contact force and friction between wheels and grounds.

Learn about the advantages and disadvantages of various types of mobility for robots and rovers, such as tracks, skid steer, differential drive, and more. Compare the mechanical complexity, weight capacity, power usage, and maneuverability of each drive option.

Skid steering is accomplished by creating a differential velocity between the inner and outer wheels. Explicit steering is accomplished by changing the heading of the wheels to cause a change in heading of the vehicle. Experimental results are gathered to provide information regarding power draw, individual wheel torque, and position information.Differential Drive Robots. These drive bases typically have two or more in-line traction or omni wheels per side (e.g., 6WD or 8WD) and may also be known as “skid-steer”, “tank drive”, or “West Coast Drive”. The Kit of Parts drivetrain is an example of a differential drive.

Learn about different wheel arrangements and control mechanisms for robots, such as differential drive, skid steering, tricycle drive and Ackermann steering. Differential drive is the most common and simple method to drive and steer a robot using two independently driven wheels. Skid steering has advantages for military armoured vehicles because it gives greater internal hull volume and improved manoeuvrability. The steering performance of an 18t 6×6 skid-steered.

capable of slip prediction for skid-steer wheeled mobile robots (SSWMRs). The proposed model outperforms the state-of-the-art in terms of both translational and rotational prediction error on a dataset composed of more than 6km worth of trajectories traversed by a skid-steer robot. We also publicly release our

Learn about the history, operation and use of skid-steer loaders, compact heavy equipment with lift arms and zero-radius turning capability. Find out how they differ from conventional front loaders and what safety precautions are needed.

fuel tank capacity of a j.d 326 skid steer

skid steer vs mecanum wheel

SY16C LIFTING PERFORMANCE SY16C PRODUCT SPECIFICATIONS Front Side ©2022 SANY America Inc. HEXPS22SY16C001 SANY America Inc. 318 Cooper Circle, Peachtree City, Georgia 30269 470.552.SANY sanyamerica.com STANDARD FEATURES Gross Power 15 hp Dig Depth 7' 9" Operating Weight 4,023 lb Bucket Breakout 3,417 lbf Short Tail Swing Boom .

skid steer differential|skid steer vs mecanum wheel