mini digger risk assessment All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this . The CASE TL100 mini track loader is a compact, ride-behind machine with a 24 hp engine and a rated operating capacity of 1,000 lbs. It has over 40 different attachment options, a pilot joystick control and a 42 in. or 36 in. track width.

0 · risk assessment for tlb

1 · plant risk assessment excavator

2 · excavator sop

3 · excavator risk assessment template

4 · excavator operator evaluation form

5 · excavator hazards and controls

They can be rented by the day, week, or month. Here are some examples of what you might .Our reputation was forged in the dirt. Tackling tough jobs in some of the most difficult locations .

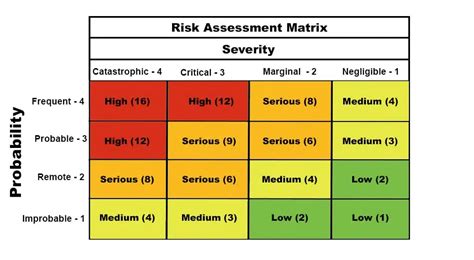

Identify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences;Operate the digger in a safe controlled manner, only in areas designated and in good lighting conditions only. Sound horn before emerging from behind a blind corner and reduce speed to .All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this .

cat skid steer how many horsepower

This Mini Digger Risk Assessment has been created to assess the risks associated with the use of mini diggers. The Mini Digger Risk Assessment will give you a good indication of the .Recognise the hazards, risks and controls required to eliminate or reduce hazards in your workplace from the use of Digger/Excavator. Create awareness about the risks from crushing, .If the Mini Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to . Excavator risk assessment templates are used to identify and assess the risks of excavators. The primary goal is to protect workers from injury or illness through effective .

Apply a risk rating based on the Risk Matrix. In the comments box, describe what the hazards are and the consequences; Specify the risk control type from the hierarchy of control at right, for .

The instructions recommended within this document apply to normal risk conditions. If the machine is to be operated in a dangerous or hostile environment, the user/client is responsible .carry out risk assessments and provide their employees with clear and appropriate information on any risks that exist in the workplace and how they intend to reduce those risksIdentify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences;

Operate the digger in a safe controlled manner, only in areas designated and in good lighting conditions only. Sound horn before emerging from behind a blind corner and reduce speed to an appropriate level.All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this Plant Risk Assessment.This Mini Digger Risk Assessment has been created to assess the risks associated with the use of mini diggers. The Mini Digger Risk Assessment will give you a good indication of the hazards associated with the activity, along with the risks and controls you should be thinking about.Recognise the hazards, risks and controls required to eliminate or reduce hazards in your workplace from the use of Digger/Excavator. Create awareness about the risks from crushing, striking, noise, exhaust fumes, vibration, underground services and more.

If the Mini Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to mitigate those additional risks. This instruction should be read in conjunction with the Risk Assessment. GENERAL SAFETY.

Excavator risk assessment templates are used to identify and assess the risks of excavators. The primary goal is to protect workers from injury or illness through effective hazard identification and risk assessment processes.Apply a risk rating based on the Risk Matrix. In the comments box, describe what the hazards are and the consequences; Specify the risk control type from the hierarchy of control at right, for each current or proposed risk control; Explain what controls will be put in place for the hazard in CONTROL DESCRIPTION.The instructions recommended within this document apply to normal risk conditions. If the machine is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to .

carry out risk assessments and provide their employees with clear and appropriate information on any risks that exist in the workplace and how they intend to reduce those risks

Identify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences;Operate the digger in a safe controlled manner, only in areas designated and in good lighting conditions only. Sound horn before emerging from behind a blind corner and reduce speed to an appropriate level.

All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this Plant Risk Assessment.This Mini Digger Risk Assessment has been created to assess the risks associated with the use of mini diggers. The Mini Digger Risk Assessment will give you a good indication of the hazards associated with the activity, along with the risks and controls you should be thinking about.Recognise the hazards, risks and controls required to eliminate or reduce hazards in your workplace from the use of Digger/Excavator. Create awareness about the risks from crushing, striking, noise, exhaust fumes, vibration, underground services and more.If the Mini Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to mitigate those additional risks. This instruction should be read in conjunction with the Risk Assessment. GENERAL SAFETY.

Excavator risk assessment templates are used to identify and assess the risks of excavators. The primary goal is to protect workers from injury or illness through effective hazard identification and risk assessment processes.Apply a risk rating based on the Risk Matrix. In the comments box, describe what the hazards are and the consequences; Specify the risk control type from the hierarchy of control at right, for each current or proposed risk control; Explain what controls will be put in place for the hazard in CONTROL DESCRIPTION.The instructions recommended within this document apply to normal risk conditions. If the machine is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to .

cat skid steer rental cost

risk assessment for tlb

cat skid steer tire sizes

plant risk assessment excavator

excavator sop

2021 John Deere 317G. 609 hours. $45,000. Mini excavators are small, tracked machines equipped with a bucket and an arm that can rotate 360 degrees. They are primarily used for digging, lifting, and carrying materials in .

mini digger risk assessment|excavator risk assessment template