tipping load on skid steer Rated operating capacity (ROC) is 50% of tipping capacity under ideal . Doggett is your best resource for construction equipment and forestry equipment in the Covington, LA area. We serve companies who are looking for new or used machinery or who require parts or repair work. Contact us today by calling (985) 893-3005.

0 · skid steer weight chart

1 · skid steer operating weight meaning

2 · skid steer bucket load capacity

3 · skid loader lift capacity

4 · skid loader bucket capacity

5 · rated operating capacity skid steer

6 · operating capacity vs tipping load

7 · dimensions of a skid steer

Bedrock Attachments proudly announces its latest lineup of Excavator Compaction Wheels, built for the rigorous demands of construction, utility, and roadwork industries. Designed with robust materials and engineered for peak efficiency, these wheels ensure superior ground compaction with minimal passes.Expanded Product

On tracked skid steers the operating capacity is 35% of the tipping load. The tipping load is measured at whatever height the loader reaches the farthest from the front axle. During the tip load tests they pull down at the location of the center of gravity of a "loaded .Only registered users can view profiles (Delete cookies)Delete cookies)On tracked skid steers the rated operating capacity is normally 35% of tipping load. The tippi. Rated operating capacity (ROC) is 50% of tipping capacity under ideal .

Learn how to calculate and compare the rated operating capacity (ROC) of skid . On tracked skid steers the operating capacity is 35% of the tipping load. The tipping load is measured at whatever height the loader reaches the farthest from the front axle. During the tip load tests they pull down at the location of the center of gravity of a "loaded bucket".

Rated operating capacity (ROC) is 50% of tipping capacity under ideal conditions, as gatractorman mentioned, for wheeled machines and 35% of tipping capacity for tracked loaders. Currently, compact track loaders and multi-terrain loaders are . Learn how to calculate and compare the rated operating capacity (ROC) of skid steer loaders, which is the maximum weight they can safely lift. Find out how ROC, tipping load, hydraulic flow, and attachment types influence the performance and suitability of .

skid steer weight chart

The tipping load is the amount of weight that would lift the rear tires when applied to the bucket at the machine’s maximum reach-point in the lift cycle. ROC is important to consider, but it has nothing to do with the breakout and lift force capabilities. Machines with equal ROC may have completely different breakout and lift force capabilities. On tracked skid steers the rated operating capacity is normally 35% of tipping load. The tipping load is literally what the skid steer will pick up but have zero weight on the rear tires, this much weight is not safe to carry around. Learn how to choose the best skid steer loader for your job based on size, width, lift type, terrain, controls and attachment compatibility. Compare wheeled and tracked models, radial and vertical lift skid steers, and standard and joystick controls.

A skid-steer also has a tipping capacity: Any weight greater than this amount will generally tip the machine forward, or the machine will simply not be able to lift it. The tipping capacity is usually about twice the weight of the ROC.

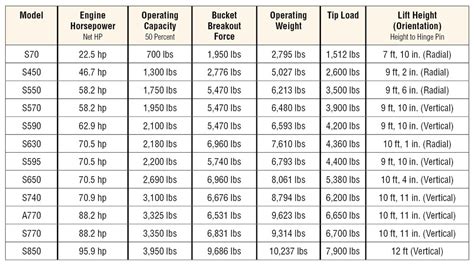

Learn how to calculate the rated operating capacity (ROC) and tipping load of skid steer loaders based on size, model, and terrain. Find out the highest-rated skid steer loader and the difference between vertical and radial lift. Compare the rated operating capacity, operating weight, engine power, lift height, length, and width of different skid steer models from various brands. Find the best skid steer for your project with this comprehensive guide and chart.In this video we give a quick breakdown of the terminology you will find on a spec sheet of compact construction equipment such as skid steers and wheel loaders to determine the lifting capacity. We go over the tipping load and operating capacity specifically to make sure you are being safe when operating your equipment. On tracked skid steers the operating capacity is 35% of the tipping load. The tipping load is measured at whatever height the loader reaches the farthest from the front axle. During the tip load tests they pull down at the location of the center of gravity of a "loaded bucket".

Rated operating capacity (ROC) is 50% of tipping capacity under ideal conditions, as gatractorman mentioned, for wheeled machines and 35% of tipping capacity for tracked loaders. Currently, compact track loaders and multi-terrain loaders are . Learn how to calculate and compare the rated operating capacity (ROC) of skid steer loaders, which is the maximum weight they can safely lift. Find out how ROC, tipping load, hydraulic flow, and attachment types influence the performance and suitability of . The tipping load is the amount of weight that would lift the rear tires when applied to the bucket at the machine’s maximum reach-point in the lift cycle. ROC is important to consider, but it has nothing to do with the breakout and lift force capabilities. Machines with equal ROC may have completely different breakout and lift force capabilities.

On tracked skid steers the rated operating capacity is normally 35% of tipping load. The tipping load is literally what the skid steer will pick up but have zero weight on the rear tires, this much weight is not safe to carry around. Learn how to choose the best skid steer loader for your job based on size, width, lift type, terrain, controls and attachment compatibility. Compare wheeled and tracked models, radial and vertical lift skid steers, and standard and joystick controls. A skid-steer also has a tipping capacity: Any weight greater than this amount will generally tip the machine forward, or the machine will simply not be able to lift it. The tipping capacity is usually about twice the weight of the ROC.

Learn how to calculate the rated operating capacity (ROC) and tipping load of skid steer loaders based on size, model, and terrain. Find out the highest-rated skid steer loader and the difference between vertical and radial lift.

Compare the rated operating capacity, operating weight, engine power, lift height, length, and width of different skid steer models from various brands. Find the best skid steer for your project with this comprehensive guide and chart.

skid steer operating weight meaning

john deere mini excavator dealers

skid steer bucket load capacity

TB2150 Compact Excavator. Unique in its class are the standard pivot boom and dozer blade increasing versatility. The cab is completely redesigned and features a suspension seat, automatic climate control, and a new color monitor panel to monitor machine performance and view the rear view camera.

tipping load on skid steer|skid steer operating weight meaning